Introduction

In the ever-evolving world of electrical installations, understanding explosion-proof LB fittings is crucial for ensuring safety and compliance. These specialized fittings are designed to contain any potential explosions that could occur within electrical systems, thus protecting both personnel and property. As we delve deeper into this topic, it’s essential to grasp what makes a fitting explosion proof and how it aligns with electrical safety standards.

Understanding Explosion-proof LB Fittings

So, what exactly is an explosion-proof LB fitting? These fittings are engineered to withstand internal explosions without allowing flames or hot gases to escape into the surrounding environment. This capability is vital in settings where flammable gases or vapors may be present, making explosion proof LB fittings indispensable in industries like oil and gas, chemical manufacturing, and pharmaceuticals.

When assessing electrical LB fittings, one must consider not only their construction but also their intended applications. For instance, certain types of EMT (Electrical Metallic Tubing) might prompt the question: Is EMT explosion proof? While standard EMT does not meet explosion-proof criteria on its own, when paired with the right components such as certified connectors and enclosures, it can contribute to a safe installation in hazardous locations.

Importance of Electrical Safety Standards

Electrical safety standards play a pivotal role in protecting lives and property from potential hazards associated with electrical installations. Adhering to these standards ensures that all components used—including explosion-proof LB fittings—meet rigorous safety requirements set forth by industry regulations. Without compliance with these standards, facilities risk facing significant dangers along with hefty fines for violations.

One of the most critical frameworks governing these safety measures is the NEC Code (National Electrical Code). The NEC code for explosion proof fittings outlines specific guidelines that must be followed to ensure proper installation and functionality in hazardous areas. By understanding this code thoroughly, electricians can make informed decisions about which products best suit their projects while maintaining compliance.

Overview of the NEC Code

The NEC Code serves as a comprehensive set of regulations aimed at safeguarding against electrical hazards across various environments. It provides detailed instructions on what constitutes an acceptable installation for items like explosion proof connectors and other critical components involved in creating safe electrical systems. Familiarity with this code not only enhances safety but also equips professionals with knowledge about product specifications such as explosion proof LB fittings sizes.

As we explore further into this subject matter, we’ll uncover more about compliance requirements under the NEC Code and how manufacturers like Crouse-Hinds have adapted their offerings—such as Crouse-Hinds Explosion-Proof LB—to meet these stringent guidelines effectively. Ultimately, investing time in understanding these elements will lead to safer work environments where reliability reigns supreme.

The Basics of Explosion-proof LB Fittings

What Makes a Fitting Explosion Proof

To answer the burning question—what makes a fitting explosion proof? It all boils down to design and construction. An explosion-proof fitting is built to contain any internal explosion and prevent it from igniting external hazardous materials, thanks to its robust materials and precise engineering. This means that when using explosion-proof LB fittings, you're not just playing it safe; you're actively preventing potential disasters.

Moreover, these fittings must adhere strictly to rigorous standards set forth by organizations like the National Electrical Code (NEC). Compliance with these standards ensures that your electrical installations are not only efficient but also safe for use in explosive environments. If you’re wondering about specific regulations, one common query is: what is the NEC code for explosion proof fittings? This code outlines essential guidelines for installation and usage.

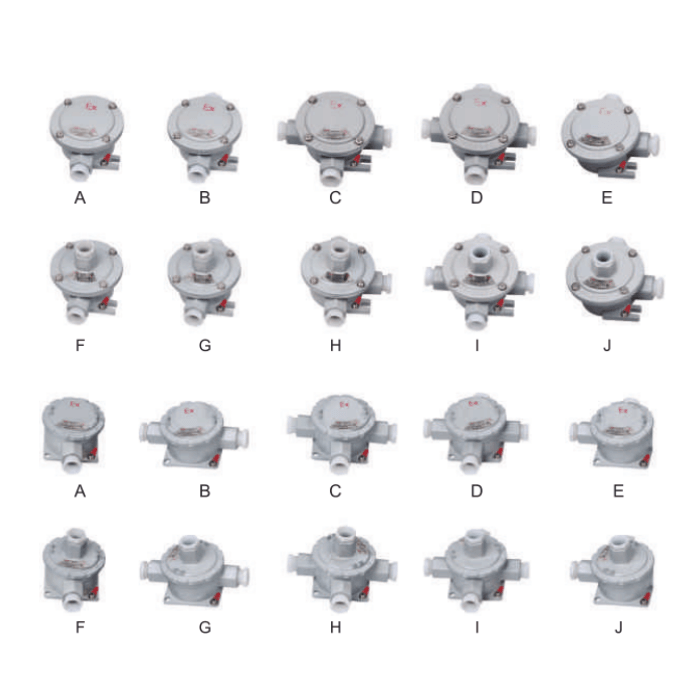

Types of Electrical LB Fittings

Electrical LB fittings come in various types tailored for specific applications and environments. The most common types include standard LBs, which are used for connecting conduit runs at right angles, as well as those specifically designed for hazardous locations—like Crouse-Hinds Explosion-Proof LB fittings that combine durability with functionality. Each type serves a unique purpose while maintaining compliance with safety standards.

Another popular option is EMT (Electrical Metallic Tubing) which often raises questions like Is EMT explosion proof? While EMT itself isn't inherently explosion proof, when paired with appropriate connectors and fittings designed for such purposes, it can be utilized safely in many applications requiring additional protection against explosions or sparks.

Choosing the right type of electrical LB fitting depends on your specific needs; whether it's moisture resistance or compatibility with certain environmental conditions, there’s an option out there tailored just for you!

Key Applications for Explosion-proof Fittings

The applications of explosion-proof LB fittings are extensive and critical across multiple industries. They are commonly found in oil refineries, chemical plants, mining operations, and other facilities where flammable gases or dust may be present. By utilizing these specialized fittings in such environments, businesses can significantly reduce risks associated with electrical failures leading to explosions or fires.

Moreover, these fittings aren’t limited just to industrial settings; they’re also increasingly used in commercial applications where safety cannot be compromised—think food processing plants or pharmaceutical manufacturing sites where cleanliness meets strict safety protocols. With an array of options available—including various sizes like explosion proof lb fittings sizes—finding suitable products tailored to your application has never been easier.

Lastly, if you’re looking to purchase reliable solutions without compromising on quality or compliance standards, check out options like explosion proof lb fittings for sale from trusted manufacturers who prioritize safety alongside performance.

Compliance with NEC Code

Ensuring compliance with the National Electrical Code (NEC) is crucial when it comes to explosion-proof LB fittings. This code provides essential guidelines and standards that manufacturers and installers must follow to ensure safety in potentially hazardous environments. By understanding the NEC code for explosion-proof fittings, you can better protect your operations and personnel from electrical hazards.

What is the NEC Code for Explosion Proof Fittings

The NEC code outlines specific regulations regarding installation and use of electrical LB fittings in explosive environments. To put it simply, the code defines what makes a fitting explosion proof and sets forth requirements that must be met to achieve certification. For example, it dictates the materials used, the design specifications, and installation practices necessary for compliance.

When asking What is the NEC code for explosion proof fittings?, it's important to note that it encompasses various aspects such as labeling, testing methods, and maintenance protocols. These guidelines ensure that all electrical LB fittings are reliable under extreme conditions while minimizing risks associated with electrical failures or sparks igniting flammable substances. Adhering to these standards not only safeguards lives but also protects property from potential disasters.

Understanding Certification Requirements

Certification is a key component of compliance with the NEC code for explosion-proof fittings. Each fitting must undergo rigorous testing by accredited organizations to verify its ability to withstand explosions without allowing flames or hot gases to escape into surrounding areas. This certification process ensures that products like Crouse-Hinds Explosion-Proof LB meet stringent safety regulations.

Understanding certification requirements also involves knowing which standards apply specifically to your application—whether you're using EMT (Electrical Metallic Tubing) or other types of conduit systems. It’s essential to confirm if your chosen products have passed these tests before making a purchase; otherwise, you risk using components that are not truly explosion proof or compliant with industry standards. Always look for labels indicating compliance when shopping for explosion-proof LB fittings for sale.

Consequences of Non-compliance

Ignoring NEC compliance can lead to dire consequences both legally and economically—think hefty fines and potential lawsuits if accidents occur due to negligence! Non-compliance can result in catastrophic incidents where improper installation or substandard materials fail during an emergency situation, leading directly to injuries or fatalities among workers exposed in hazardous environments.

Moreover, using non-compliant electrical LB fittings may void warranties from manufacturers like Jinrong or Crouse-Hinds, leaving users without recourse should issues arise later on down the line. The financial implications of accidents caused by non-compliance extend beyond immediate costs; they can damage reputations and erode trust within industries reliant on safe practices around electrical installations.

Assessing Explosion-proof LB Fitting Sizes

When it comes to explosion-proof LB fittings, size matters—quite literally! Selecting the appropriate size ensures that these critical components can effectively contain any potential explosions while maintaining the integrity of your electrical systems. Understanding the various sizes available is essential for compliance with safety standards and optimal performance.

Explosion Proof LB Fittings Sizes Explained

Explosion-proof LB fittings come in various sizes to accommodate different conduit and cable configurations. These fittings are designed to provide a secure connection while preventing the escape of ignitable gases or vapors, which is crucial in hazardous environments. Each size is tailored to meet specific requirements based on factors such as conduit type and installation space.

What makes a fitting explosion proof? It’s all about their construction and design, which includes robust materials that can withstand extreme conditions. For instance, Crouse-Hinds Explosion-Proof LB fittings are engineered with durable metals that not only resist corrosion but also endure high-pressure scenarios—making them ideal for demanding applications where safety cannot be compromised.

Choosing the Right Size for Your Application

Choosing the right size of explosion-proof LB fittings is vital for ensuring proper functionality and compliance with the NEC code for explosion proof fittings. When selecting a fitting, consider factors like conduit diameter, environmental conditions, and any applicable regulations governing your specific industry. It's crucial to match your electrical lb fittings with both existing systems and future expansion plans.

To simplify your decision-making process, consult manufacturer guidelines or industry standards that specify sizing requirements based on application type. This way, you can avoid common pitfalls associated with incorrect sizing—such as increased risk of electrical failure or even hazardous incidents in explosive atmospheres. Remember: when it comes to safety in potentially dangerous environments, there's no room for guesswork!

Common Issues with Incorrect Sizing

One of the most frequent issues arising from incorrect sizing of explosion-proof LB fittings is inadequate sealing against explosive gases or vapors. If a fitting is too small, it may not provide an effective barrier; if it's too large, it might lead to instability within the electrical system itself—both scenarios pose serious risks!

Additionally, using improperly sized electrical lb fittings can result in costly downtime due to repairs or replacements when equipment fails under pressure. Furthermore, failure to comply with what is the NEC code for explosion proof fittings could lead to penalties or increased liability in case of an incident; after all, no one wants their project flagged by inspectors due to negligence regarding safety standards.

In conclusion, always prioritize selecting appropriately sized explosion-proof LB fittings that meet both operational needs and regulatory requirements—your safety depends on it!

The Role of Crouse-Hinds in the Industry

Crouse-Hinds has established itself as a leader in the production of explosion-proof electrical LB fittings, providing solutions that prioritize safety and reliability. Their products are designed to meet rigorous standards, ensuring compliance with the NEC code for explosion proof fittings. With a strong focus on innovation, Crouse-Hinds continues to set the bar high for what makes a fitting explosion proof.

Overview of Crouse-Hinds Explosion-Proof LB

Crouse-Hinds Explosion-Proof LB fittings are engineered specifically for hazardous locations where flammable gases or vapors may be present. These electrical LB fittings feature robust construction that prevents ignition sources from escaping into the surrounding environment. What makes a fitting explosion proof is not just its physical design but also its ability to contain any potential explosions within the fitting itself, making it an essential component in various industries.

Benefits of Choosing Crouse-Hinds Products

Choosing Crouse-Hinds products comes with numerous benefits, including their proven track record in safety and durability. Their explosion-proof LB fittings are rigorously tested to ensure they meet or exceed industry standards, providing peace of mind for users concerned about compliance with NEC code regulations. Additionally, customers appreciate the extensive support offered by Crouse-Hinds, making it easy to find the right explosion proof LB fittings sizes and configurations for specific applications.

Real World Applications of Crouse-Hinds

Crouse-Hinds products can be found in numerous real-world applications across various sectors such as oil and gas, chemical processing, and manufacturing facilities where electrical safety is paramount. The versatility of their explosion-proof LB fittings allows them to be used effectively in environments where EMT might not be suitable due to safety concerns—making them indispensable tools for engineers and electricians alike. Whether you’re searching for explosion proof connectors or specific electrical LB fittings for sale, Crouse-Hinds offers solutions tailored to meet diverse operational needs.

Long-lasting Solutions with Jinrong

In the realm of electrical safety, Jinrong stands out as a beacon of quality and reliability. With a strong legacy in explosion-proof manufacturing, the company has consistently delivered products that meet stringent safety standards. Their commitment to excellence ensures that customers can trust their explosion-proof LB fittings to perform under demanding conditions.

Jinrong's Legacy in Explosion-proof Manufacturing

Jinrong has carved out a significant niche in the market for explosion-proof LB fittings, known for their rigorous testing and adherence to industry standards. What makes a fitting explosion proof? It’s all about the design and materials used; Jinrong’s fittings are engineered to withstand harsh environments while preventing ignition sources from escaping. This dedication to quality has earned them a reputation as a leader in explosion-proof solutions.

Diverse Product Range for Electrical Safety

Their offerings include various sizes of explosion proof LB fittings designed to accommodate diverse installation needs while ensuring compliance with regulations like the NEC code for explosion proof fittings. From connectors to conduits, they have everything you need for robust electrical safety solutions.

Supporting Distributors with Quality Products

Jinrong understands the importance of supporting distributors by providing high-quality products that are both reliable and compliant with safety standards. Their commitment extends beyond just manufacturing; they actively engage with distributors to ensure they have access to essential resources like detailed product specifications and training on how these products meet NEC code requirements. By choosing Jinrong products, distributors can confidently offer their customers top-notch solutions such as Crouse-Hinds Explosion-Proof LB fittings alongside other exceptional options available for sale.

Conclusion

In the realm of electrical safety, ensuring compliance with established standards is paramount. Explosion-proof LB fittings play a critical role in safeguarding environments where flammable materials may be present. By adhering to the NEC code for explosion proof fittings, you not only protect your installations but also contribute to a safer workplace.

Ensuring Compliance for Safety

Understanding what makes a fitting explosion proof is essential for any project involving electrical LB fittings. The NEC code outlines specific requirements that must be met to ensure these fittings can withstand hazardous conditions without failure. Ignoring these guidelines can lead to severe consequences, including accidents and legal repercussions—so compliance isn't just advisable; it's imperative.

Choosing the Right Explosion-proof Fittings

When selecting explosion proof LB fittings, consider factors such as application type and environmental conditions. Not all products are created equal; some may be suited for specific scenarios while others might fall short in crucial aspects like durability or resistance to harsh elements. Additionally, understanding explosion proof LB fittings sizes is vital—too small and they won't fit properly; too large and they could compromise safety.

Investing in Trusted Brands for Reliability

Brands like Crouse-Hinds have established themselves as leaders in the industry by consistently delivering reliable explosion-proof solutions, including their renowned Crouse-Hinds Explosion-Proof LB offerings. Investing in trusted brands ensures that you receive quality products designed specifically for safety and performance under pressure. Moreover, exploring options like explosion proof connectors can further enhance your systems' integrity while providing peace of mind.