Introduction

In the world of electrical enclosures, understanding NEMA ratings is crucial for ensuring safety and efficiency. These ratings, established by the National Electrical Manufacturers Association (NEMA), provide guidelines for various types of enclosures that protect electrical equipment from environmental hazards. Among these, the NEMA 12 rating stands out as a popular choice for its ability to safeguard sensitive components from dust and moisture in industrial settings.

Understanding NEMA Ratings

NEMA ratings serve as a benchmark for evaluating the performance of enclosures under specific conditions. They categorize various NEMA enclosure types based on their ability to withstand environmental factors such as water, dust, and corrosion. The different NEMA box ratings help manufacturers and engineers select the right enclosure that meets their operational needs while ensuring compliance with industry standards.

Importance of NEMA 12 Rating

The NEMA 12 rating is particularly important because it indicates an enclosure's effectiveness in protecting against non-hazardous dust and dripping water. This makes it ideal for environments where moisture or particulate matter could compromise electrical systems without exposing them to more severe threats like rain or splashing water. By adhering to the NEMA 12 specifications, industries can ensure longevity and reliability in their equipment operations.

Applications of NEMA 12 Enclosures

NEMA 12 enclosures find applications across various sectors including manufacturing, food processing, and pharmaceuticals, where cleanliness and protection are paramount. These versatile enclosures are designed to house control panels, junction boxes, and other critical electronic components safely away from harmful elements. Their adaptability makes them a preferred choice in both industrial facilities and commercial environments that require durable solutions tailored to unique challenges.

What is NEMA?

When it comes to electrical enclosures and equipment, the National Electrical Manufacturers Association (NEMA) sets the gold standard. NEMA ratings provide a classification system that helps manufacturers and users understand how well an enclosure can protect against environmental factors. By understanding these ratings, one can make informed decisions about the right NEMA enclosure for specific applications.

Overview of NEMA Standards

NEMA standards are designed to ensure safety, reliability, and performance in electrical installations. These standards outline various types of enclosures based on their ability to withstand different environmental challenges such as dust, moisture, and corrosive substances. The NEMA 12 rating specifically indicates that an enclosure is suitable for indoor use in non-hazardous locations, protecting against dust and dripping water—ideal for many industrial settings.

Different NEMA Enclosure Types

There are numerous NEMA enclosure types tailored to meet diverse needs across industries. Each type serves a unique purpose; for instance, while the NEMA 4 rating protects against water ingress from splashing or hose-directed water, the NEMA 12 rating focuses on safeguarding sensitive equipment from dust and moisture without requiring extensive sealing measures. Understanding these distinctions helps businesses choose the appropriate nema box ratings for their specific operational environments.

The Role of NEMA Ratings in Industry

NEMA ratings play a crucial role in various industries by providing guidelines that ensure safety and compliance with regulations. These ratings help engineers select suitable nema enclosure types based on environmental conditions they expect to encounter—whether it's heavy machinery in manufacturing or sensitive electronics in food processing facilities. Ultimately, adhering to these nema ratings not only enhances operational efficiency but also protects investments by prolonging equipment lifespan.

NEMA 12 Rating Explained

When it comes to NEMA ratings, the NEMA 12 rating stands out for its specific applications and protective qualities. This rating is part of a broader classification system established by the National Electrical Manufacturers Association (NEMA) to ensure electrical enclosures meet certain standards for safety and performance. Understanding what the NEMA 12 rating entails is essential for selecting the right enclosure for your needs.

Definition and Specifications

The NEMA 12 rating refers to enclosures designed to provide a moderate level of protection against dust, dirt, and moisture. Specifically, these enclosures are constructed to prevent ingress of non-hazardous dust and dripping water, making them ideal for indoor use in environments where such contaminants may be present. With a typical construction from materials like steel or fiberglass, a NEMA 12 enclosure is robust enough to handle various industrial settings while maintaining necessary operational standards.

In terms of specifications, NEMA 12 boxes are often rated for indoor use only and should not be exposed directly to rain or extreme environmental conditions. They typically feature removable covers and gaskets that enhance their sealing capabilities against particles and moisture. Understanding these specifications is crucial when evaluating different NEMA enclosure types that best suit your application.

Comparison with Other NEMA Ratings

When comparing the NEMA 12 rating with other enclosure ratings such as NEMA 4 or NEMA 6, notable differences emerge in terms of protection levels and intended environments. For instance, while both NEMA 4 and NEMA 6 provide superior water resistance suitable for outdoor applications, they do not offer the same level of dust protection as a typical NEMA 12 enclosure does indoors. Additionally, unlike the more rugged outdoor-rated enclosures, the primary focus of the NEMA 12 rating is on dust control rather than exposure to harsh weather conditions.

Another point of comparison lies in their construction materials; while all ratings aim for durability, those rated higher than NEMA 12 often utilize more robust materials designed specifically for harsher environments. This distinction helps users select appropriate options based on their specific needs—whether they require heavy-duty outdoor protection or reliable indoor safeguarding against particulates. Ultimately, understanding these differences can help streamline your decision-making process regarding which type of enclosure suits your application best.

Key Features of NEMA 12 Enclosure

NEMA 12 enclosures come equipped with several key features that enhance their functionality across various applications. One significant feature includes an integrated gasket system that ensures tight sealing around doors or access points—this minimizes any potential ingress from dust or moisture while allowing easy access when needed. Additionally, many models are designed with ventilation options that help maintain optimal internal temperatures without compromising protective qualities.

Another important aspect is their versatility; these enclosures can accommodate various equipment sizes and configurations due to customizable mounting options inside the box itself. Moreover, many manufacturers offer additional accessories like racks or shelves tailored specifically for use within a NEMA 12 enclosure—making them adaptable solutions across multiple industries including manufacturing and food processing sectors where cleanliness matters immensely.

In summary, understanding what defines a typical nema box rated as Nema Type allows businesses to make informed decisions about which products will best serve their operational requirements while ensuring compliance with industry standards.

Benefits of NEMA 12 Enclosures

NEMA 12 enclosures are the unsung heroes of industrial settings, providing a robust solution to various environmental challenges. With their specific NEMA ratings, these enclosures offer unique advantages that enhance operational efficiency and safety. Here, we delve into the key benefits of NEMA 12 enclosures that make them a preferred choice across multiple industries.

Protection Against Dust and Moisture

One of the standout features of the NEMA 12 rating is its exceptional protection against dust and moisture intrusion. These enclosures are designed to keep harmful particles at bay, ensuring that sensitive equipment remains safe from contamination. In environments where dust and moisture can wreak havoc on machinery, opting for a NEMA 12 enclosure is a no-brainer for maintaining operational integrity.

The ability to safeguard against such elements not only prolongs the lifespan of equipment but also minimizes maintenance costs associated with repairs or replacements. The design characteristics inherent in NEMA enclosure types like the NEMA 12 ensure that your valuable electronics remain shielded from grime and humidity. Ultimately, this level of protection translates into enhanced reliability and peace of mind for users.

Durability and Longevity

Durability is another hallmark benefit associated with NEMA 12 enclosures, making them ideal for demanding industrial applications. Constructed from high-quality materials, these enclosures are built to withstand harsh conditions while maintaining their structural integrity over time. When you invest in a NEMA 12 enclosure, you're not just buying a box; you’re securing long-term performance.

The longevity offered by these enclosures means fewer replacements and lower overall costs in the long run—a win-win situation for any business looking to optimize its budget while ensuring equipment safety. Moreover, as part of various NEMA enclosure ratings, the durability factor solidifies their standing as reliable options in sectors like manufacturing and food processing. Choosing a durable solution like the NEMA 12 ensures your operations run smoothly without unexpected interruptions.

Cost-Effectiveness in Various Applications

Cost-effectiveness might not be the first thing that comes to mind when considering different NEMA box ratings; however, it’s an essential aspect worth highlighting regarding the NEMA 12 rating specifically. These enclosures strike an impressive balance between affordability and functionality—making them accessible options for businesses without sacrificing quality or safety standards. Their versatility allows them to be employed across various applications while keeping costs manageable.

In industries where budgets can be tight yet operational demands high, opting for a cost-effective solution like a NEMA 12 enclosure can lead to significant savings over time through reduced maintenance expenditures and extended equipment life cycles. This makes it easier for companies to allocate resources effectively while still adhering to industry compliance standards related to safety and performance metrics tied to different NEMA enclosure types. Investing in a reliable yet economical choice pays dividends down the line!

Industries Utilizing NEMA 12

NEMA 12 enclosures are not just a technical specification; they play a crucial role across various industries. These NEMA enclosure types are designed to provide protection from dust, dirt, and moisture, making them ideal for environments where equipment is exposed to challenging conditions. Let's delve into how different sectors leverage the benefits of the NEMA 12 rating.

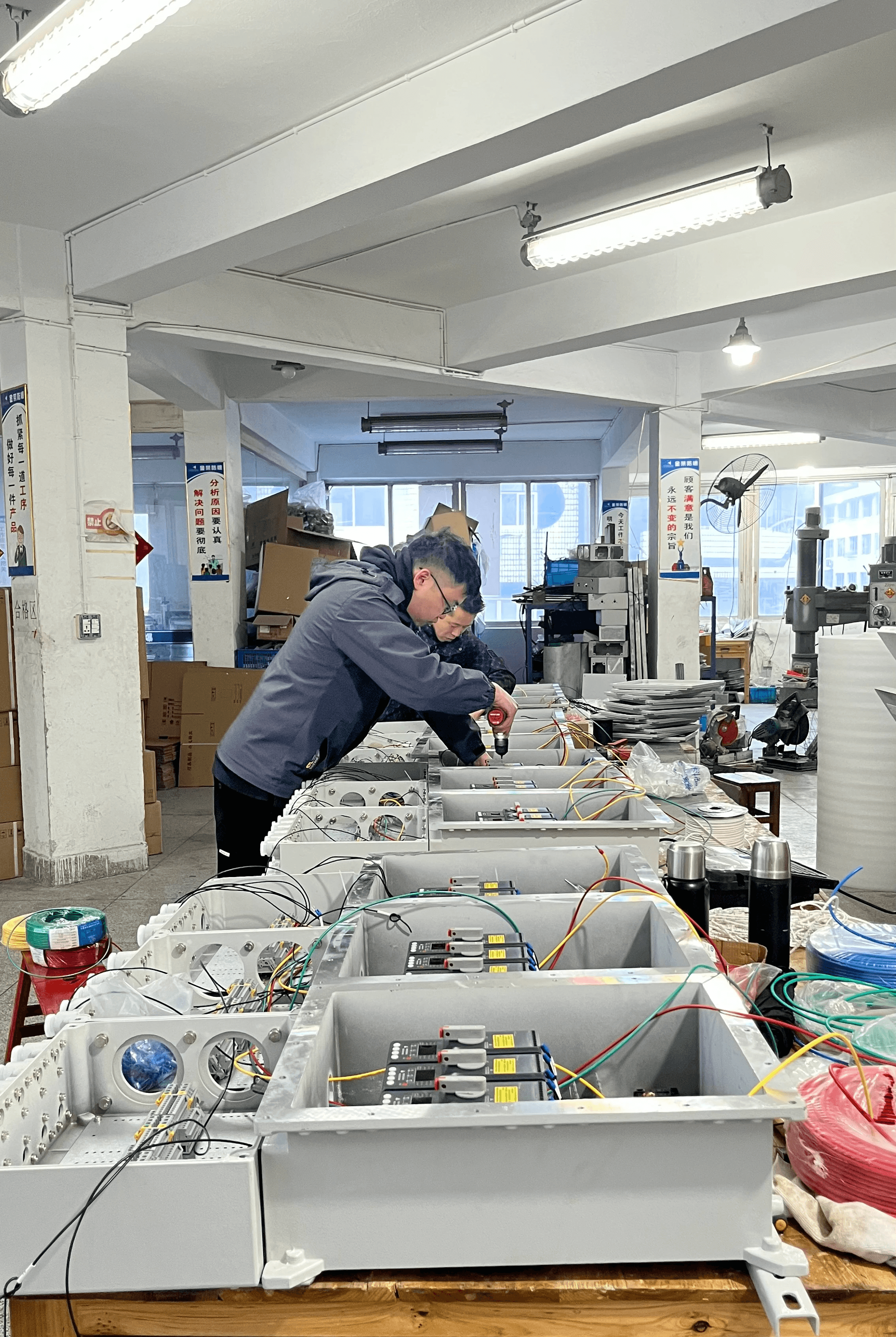

Manufacturing and Industrial Settings

In manufacturing and industrial settings, equipment is often subjected to harsh conditions that can compromise performance and safety. The NEMA 12 rating offers an effective solution by providing robust protection against dust and non-corrosive liquids. This makes NEMA 12 enclosures particularly popular for housing electrical controls, motors, and other sensitive machinery that require a clean environment to operate efficiently.

Manufacturers benefit from using NEMA box ratings as they ensure compliance with industry standards while protecting vital components from contaminants. By investing in a reliable NEMA 12 enclosure, businesses can minimize downtime caused by equipment failure due to environmental factors. Furthermore, these enclosures contribute to longer equipment lifespan, ultimately leading to significant cost savings.

Food Processing and Pharmaceuticals

In the food processing and pharmaceutical industries, cleanliness is paramount; any contamination can lead to serious health risks or product recalls. Here, the NEMA 12 enclosure proves invaluable due to its ability to shield sensitive electronic components from dust and moisture while maintaining hygienic conditions. With its solid construction and protective features, it ensures that machinery operates smoothly without compromising product safety.

The stringent regulations in these industries make adherence to compliance standards essential; utilizing enclosures with the appropriate NEMA ratings helps companies meet these requirements effectively. Moreover, using a NEMA 12 enclosure allows for easier cleaning processes since they are designed with smooth surfaces that resist contamination buildup. This not only enhances operational efficiency but also fosters consumer trust in product quality.

Jinrong's Role in NEMA 12 Solutions

Jinrong stands out as a key player in providing high-quality solutions featuring the coveted NEMA 12 rating across various industries. With extensive experience in manufacturing durable enclosures tailored for specific needs, Jinrong ensures that clients receive products meeting stringent performance criteria associated with different NEMA enclosure types. Their commitment extends beyond just providing products; they also offer expert guidance on selecting the right enclosure based on individual application requirements.

By prioritizing innovation and reliability in their offerings, Jinrong has established itself as a trusted partner for businesses looking for effective solutions involving NEMA box ratings like the NEMA 12 enclosure. Their products often exceed industry expectations while ensuring compliance with relevant standards—an essential factor in today’s competitive landscape. As industries continue evolving towards more automated processes requiring robust protection measures, Jinrong remains dedicated to delivering superior quality solutions built around the principles of durability and efficiency.

Choosing the Right NEMA Enclosure

Selecting the appropriate NEMA enclosure is crucial for ensuring optimal protection for your equipment and compliance with industry standards. With various NEMA enclosure types available, understanding the specific requirements of your application is essential. When it comes to NEMA ratings, particularly the NEMA 12 rating, there are several factors to consider that can significantly impact performance and longevity.

Factors to Consider in NEMA Ratings

When evaluating NEMA enclosure ratings, start by considering the environmental conditions your equipment will face. The NEMA 12 rating is specifically designed for indoor use where dust, dirt, and moisture are a concern but not extreme wetness or corrosive elements. Additionally, think about temperature variations, as some enclosures may offer better insulation against heat or cold depending on their construction materials and design.

Another critical factor is the size of the enclosure; it needs to accommodate all necessary components while allowing for adequate airflow and accessibility. Ensure that you check the specifications of different NEMA box ratings to find one that matches your dimensions without compromising safety or functionality. Lastly, consider future scalability—selecting a slightly larger enclosure could save you from having to upgrade later as your needs expand.

Common Mistakes to Avoid

One common error when selecting a NEMA enclosure is overlooking specific environmental factors that might affect performance over time. For instance, assuming that all dust-tight enclosures are created equal can lead you astray; not all enclosures rated under different NEMA types provide identical levels of protection against contaminants like dust or moisture. Always double-check that you're choosing an enclosure suited for your specific application rather than making assumptions based on general descriptions.

Another mistake often made is neglecting proper installation practices once you've chosen a suitable NEMA 12 enclosure. Even the best-rated boxes can falter if they aren’t installed correctly; ensure gaskets are sealed properly and that mounting hardware is secure to maintain their protective qualities fully. Finally, don’t forget about compliance standards—failing to adhere could lead not only to operational issues but also legal ramifications down the line.

How to Meet Compliance Standards

Meeting compliance standards starts with understanding which regulations apply specifically to your industry and how they relate to different NEMA ratings—including those for a quality NEMA 12 enclosure. Familiarize yourself with local codes as well as national guidelines set forth by organizations like ANSI (American National Standards Institute). This knowledge will help you choose an appropriate enclosure type while ensuring it meets both safety requirements and operational effectiveness.

Documentation plays a significant role in compliance; keep records of all specifications related to your selected enclosures along with any certifications they possess under relevant standards like UL (Underwriters Laboratories) or CSA (Canadian Standards Association). Regular audits and inspections can also assist in maintaining compliance over time—make this part of routine maintenance checks so any potential issues can be addressed promptly before they escalate into major problems.

By carefully considering these factors when choosing a suitable NEMA box rating like the reliable NEMA 12 rating, avoiding common pitfalls during selection and installation processes, and adhering closely to compliance protocols, you'll ensure optimal performance for years ahead.

Conclusion

In summary, the NEMA 12 enclosure offers a robust solution for protecting sensitive electrical equipment from dust and moisture. With its durable design and cost-effectiveness, the NEMA 12 rating stands out among various NEMA enclosure types, making it a popular choice across multiple industries. By understanding the advantages of NEMA 12 enclosures, businesses can enhance operational efficiency while ensuring compliance with necessary standards.

Summary of NEMA 12 Enclosure Advantages

The NEMA 12 rating is celebrated for its ability to safeguard equipment from both dust and non-corrosive liquids. This makes it particularly valuable in environments where cleanliness is paramount, such as food processing or pharmaceutical settings. Additionally, the durability of a NEMA 12 enclosure means that companies can rely on these solutions for long-term use without frequent replacements, ultimately leading to cost savings.

Future Trends in NEMA Ratings

As technology advances and industries evolve, we can expect to see changes in NEMA ratings to accommodate new challenges. The rise of smart manufacturing may lead to more specialized NEMA enclosure types that offer enhanced features like connectivity or integrated monitoring systems. Furthermore, sustainability will likely play a larger role in future designs, with manufacturers focusing on eco-friendly materials while maintaining compliance with existing nema box ratings.

Jinrong's Commitment to Quality and Reliability

At Jinrong, our dedication to quality ensures that our products meet the stringent requirements set forth by various nema enclosure ratings. We pride ourselves on providing reliable solutions tailored specifically for demanding applications across diverse industries utilizing the nema type system effectively. Our commitment extends beyond just product quality; we aim to support our customers in navigating their unique needs related to nema 12 enclosures and beyond.