Introduction

What is NEMA 4X Rating?

The NEMA 4X rating signifies an enclosure's ability to resist water ingress, dust, and corrosion from various chemicals. Unlike its counterpart, the standard NEMA 4 rating primarily focuses on water protection but does not address corrosion resistance. Therefore, if you're in need of an enclosure that can handle both moisture and chemical exposure without breaking a sweat, look no further than the NEMA 4X electrical enclosure.

Importance of NEMA Ratings

NEMA ratings serve as a universal language for understanding the protective capabilities of electrical enclosures across various industries. They provide essential information about how well an enclosure will perform under specific environmental conditions, ensuring equipment longevity and operational efficiency. Without these ratings, selecting the right enclosure could be akin to navigating a maze blindfolded—confusing and potentially detrimental to your operations.

Overview of NEMA Enclosure Ratings

NEMA enclosure ratings are categorized by numbers that denote their suitability for different environments—from indoor use to extreme outdoor conditions. Each rating outlines specific criteria regarding protection against elements like water, dust, and corrosive substances. The spectrum ranges from basic enclosures like NEMA 1 to more robust options such as NEMA 6P or our focus today—the resilient NEMA 4X enclosure.

Understanding NEMA Ratings

NEMA ratings serve as a crucial benchmark for determining the suitability of electrical enclosures in various environments. The National Electrical Manufacturers Association (NEMA) establishes these ratings to ensure that enclosures can withstand specific conditions while protecting electrical components. Understanding NEMA enclosure ratings is essential for selecting the right enclosure, especially when considering the highly regarded NEMA 4X rating.

Definition of NEMA Ratings

NEMA ratings are standardized classifications that indicate how well an electrical enclosure can protect its contents from environmental hazards. These ratings cover a range of factors, including moisture, dust, and corrosive elements, allowing users to assess whether a particular enclosure meets their needs. The NEMA 4X rating specifically denotes an enclosure's ability to withstand water and corrosion while providing adequate protection against dust and debris.

Common NEMA Ratings Explained

There are several common NEMA ratings that cater to various applications and environments. For instance, the NEMA 1 rating offers basic protection against non-hazardous indoor environments but falls short in harsher conditions. In contrast, the NEMA 4 rating provides a higher level of protection against water ingress but lacks the corrosion resistance found in the more specialized NEMA 4X rating, making it vital to choose wisely based on your specific requirements.

Differences Between NEMA Ratings

The differences between various NEMA ratings can significantly impact their application and performance in real-world scenarios. While some ratings focus primarily on moisture resistance like NEMA 4 or even provide additional dust protection like NEMA 3R, others like the NEMA 4X rating include enhanced features for corrosive environments as well. This distinction is critical for industries dealing with harsh chemicals or extreme weather conditions where choosing an appropriate enclosure could mean the difference between equipment longevity and failure.

The NEMA 4X Rating Explained

The NEMA 4X rating is a critical classification in the world of electrical enclosures, designed to provide robust protection against various environmental hazards. This rating signifies that an enclosure can withstand water, dust, and even corrosive agents, making it ideal for demanding industrial settings. Understanding the nuances of the NEMA 4X rating helps businesses select the right enclosure for their specific needs.

Key Features of NEMA 4X

NEMA 4X enclosures boast several key features that set them apart from other ratings. Firstly, they are constructed to be watertight and dust-tight, ensuring that no harmful elements infiltrate sensitive electrical components. Additionally, these enclosures are resistant to corrosion from chemicals and harsh environments, which makes them perfect for outdoor applications or industries where exposure to corrosive substances is a concern.

Another significant feature of the NEMA 4X rating is its ability to endure extreme temperature variations while maintaining structural integrity. This durability allows businesses to operate confidently in fluctuating climates without worrying about enclosure failure. Furthermore, many NEMA 4X enclosures come equipped with gaskets and seals that enhance their protective capabilities against moisture ingress.

Comparison with NEMA 4

While both NEMA 4 and NEMA 4X ratings offer excellent protection against water and dust, they differ primarily in their resistance to corrosion. The standard NEMA 4 enclosure provides adequate protection against splashing water and windblown dust but does not specify resistance to corrosive substances. In contrast, the NEMA 4X rating explicitly includes this vital feature, making it suitable for environments where exposure to chemicals is common.

Moreover, when considering applications in marine or chemical processing industries, choosing a NEMA 4X enclosure over a standard NEMA 4 can make all the difference in longevity and reliability. It’s essential for companies operating in such environments to understand these differences so they can make informed decisions regarding their equipment protection strategies. Ultimately, while both ratings serve important functions within various industries, selecting between them hinges on specific environmental conditions faced by each application.

Applications of NEMA 4X

The versatility of the NEMA 4X rating means it finds applications across numerous sectors where durability is paramount. Industries such as food processing often utilize NEMA 4X enclosures due to their ability to withstand frequent washdowns with high-pressure water streams and exposure to harsh cleaning agents without deteriorating over time. Similarly, pharmaceutical manufacturers rely on these enclosures for protecting sensitive equipment from contamination during production processes.

Additionally, many outdoor telecommunications installations benefit from using a NEMA 4X electrical enclosure as they provide reliable performance despite unpredictable weather conditions like rain or snow accumulation. Other sectors such as wastewater treatment facilities also leverage this robust rating due to its excellent performance under varying humidity levels and potential chemical exposures inherent in such environments. Overall, understanding where and how the NEMA 4X can be applied ensures optimal operational efficiency across diverse industries.

NEMA 4X Enclosure: Benefits and Uses

Advantages of NEMA 4X Enclosures

NEMA 4X enclosures offer a plethora of benefits that make them a popular choice among industries requiring robust protection for electrical components. First and foremost, these enclosures are resistant to water, dust, and corrosion—an essential feature for environments exposed to moisture or harsh chemicals. Additionally, their durable construction provides excellent mechanical strength, which helps protect sensitive equipment from physical damage.

Another significant advantage of NEMA 4X enclosures is their versatility across various applications. Whether you're dealing with outdoor installations or areas prone to corrosive substances, these enclosures can handle it all while maintaining compliance with stringent NEMA ratings standards. With their ability to endure extreme conditions, investing in a NEMA 4X electrical enclosure often translates into lower maintenance costs over time.

Lastly, ease of installation and accessibility are key factors that enhance the appeal of NEMA 4X enclosures. Many models come equipped with features like hinged doors and removable panels that simplify access for maintenance or inspection purposes. This user-friendly design not only saves time but also contributes to overall operational efficiency in demanding environments.

Industries Utilizing NEMA 4X

The versatility of the NEMA 4X rating means it's widely adopted across numerous industries requiring reliable protection for their equipment. For instance, manufacturing plants often utilize these enclosures due to their resilience against dust and moisture—a common issue in production settings where machinery operates continuously under challenging conditions. Similarly, food processing facilities benefit from the corrosion resistance provided by NEMA 4X ratings; this is crucial in maintaining hygiene standards while safeguarding electrical components.

Moreover, sectors such as pharmaceuticals and chemicals rely heavily on NEMA-rated enclosures because they frequently encounter corrosive agents that could compromise equipment performance if not adequately protected. Water treatment facilities also favor these robust solutions since they must withstand exposure to wet environments while ensuring compliance with safety regulations. As you can see, a diverse range of industries recognizes the value offered by using a reliable enclosure with a solid NEMA rating like the 4X.

In addition to traditional sectors like manufacturing and food processing, emerging fields such as renewable energy are increasingly incorporating NEMA 4X solutions into their designs as well. Solar power installations often require durable enclosures capable of enduring outdoor elements without sacrificing functionality or safety—qualities inherent in any good enclosure meeting the stringent criteria set forth by various nema ratings.

Selecting the Right NEMA 4X Enclosure

Choosing an appropriate NEMA 4X enclosure involves several considerations tailored specifically to your application needs and environmental factors at play. Start by assessing your equipment's dimensions; ensuring proper fit within an enclosure is critical for effective operation while minimizing potential hazards associated with overcrowding or inadequate ventilation within confined spaces designated by nema enclosure ratings guidelines.

Next up is evaluating environmental conditions where this electrical enclosure will be installed—think humidity levels or exposure risks related directly back towards those pesky corrosive substances we mentioned earlier! A thorough understanding will help narrow down options based on durability requirements aligned closely alongside specific industry standards relevant within each sector utilizing nema ratings effectively throughout operations today.

Finally—and perhaps most importantly—consider any additional features you may need when selecting your perfect match: Are there specific mounting options required? Do accessibility concerns play an integral role during maintenance checks? By addressing these questions upfront before making decisions about which particular model suits best according towards unique circumstances surrounding intended use cases involving nema rated products overall!

Assessing Environmental Conditions

Factors Affecting NEMA 4X Performance

Several factors can impact the performance of a NEMA 4X enclosure, including exposure to water, dust, and corrosive substances. The design of a NEMA 4X electrical enclosure ensures that it provides excellent protection against moisture and contaminants, but its effectiveness can diminish under extreme conditions. Additionally, the installation location—be it indoors or outdoors—plays a significant role in determining how well the enclosure will hold up over time.

Another factor to consider is the temperature range in which the NEMA 4X enclosure will operate. Extreme heat or cold can affect both the materials used in manufacturing and the electronic equipment housed within. Therefore, it's essential to assess your specific environment carefully to ensure that you choose an appropriate enclosure that meets your needs.

Impacts of Corrosive Environments

Corrosive environments pose unique challenges for any electrical equipment and its housing, making it vital to consider when selecting a NEMA 4X enclosure. The X in NEMA 4X signifies additional protection against corrosion compared to standard NEMA 4 ratings; however, not all materials are created equal when faced with harsh chemicals or saltwater exposure. For instance, stainless steel enclosures often offer superior resistance against rust and degradation compared to other materials.

In industries like chemical processing or marine applications where corrosive agents abound, opting for a high-quality NEMA 4X electrical enclosure is non-negotiable. Failure to account for these environmental factors could lead to premature failure of both the equipment and its protective housing—an expensive mistake no one wants to make! Thus, understanding how corrosive elements interact with different materials is key when evaluating your options.

Humidity and Temperature Considerations

Humidity levels also play a significant role in determining how effective a NEMA 4X rating will be in protecting sensitive electrical components. High humidity can lead to condensation inside enclosures if they are not properly ventilated or sealed—potentially causing short circuits or equipment failure over time. Therefore, while selecting an enclosure with an appropriate rating is essential, considering additional features such as ventilation systems may further enhance reliability.

Temperature variations are another critical aspect of environmental assessment when dealing with NEMA ratings. Enclosures must be rated not only for their ability to withstand moisture but also for their thermal performance under varying conditions—from frigid cold spells to intense heat waves. Ensuring that your chosen NEMA 4X enclosure meets these temperature requirements will help maintain optimal operational efficiency.

Jinrong's Role in NEMA 4X Manufacturing

Overview of Jinrong's Expertise

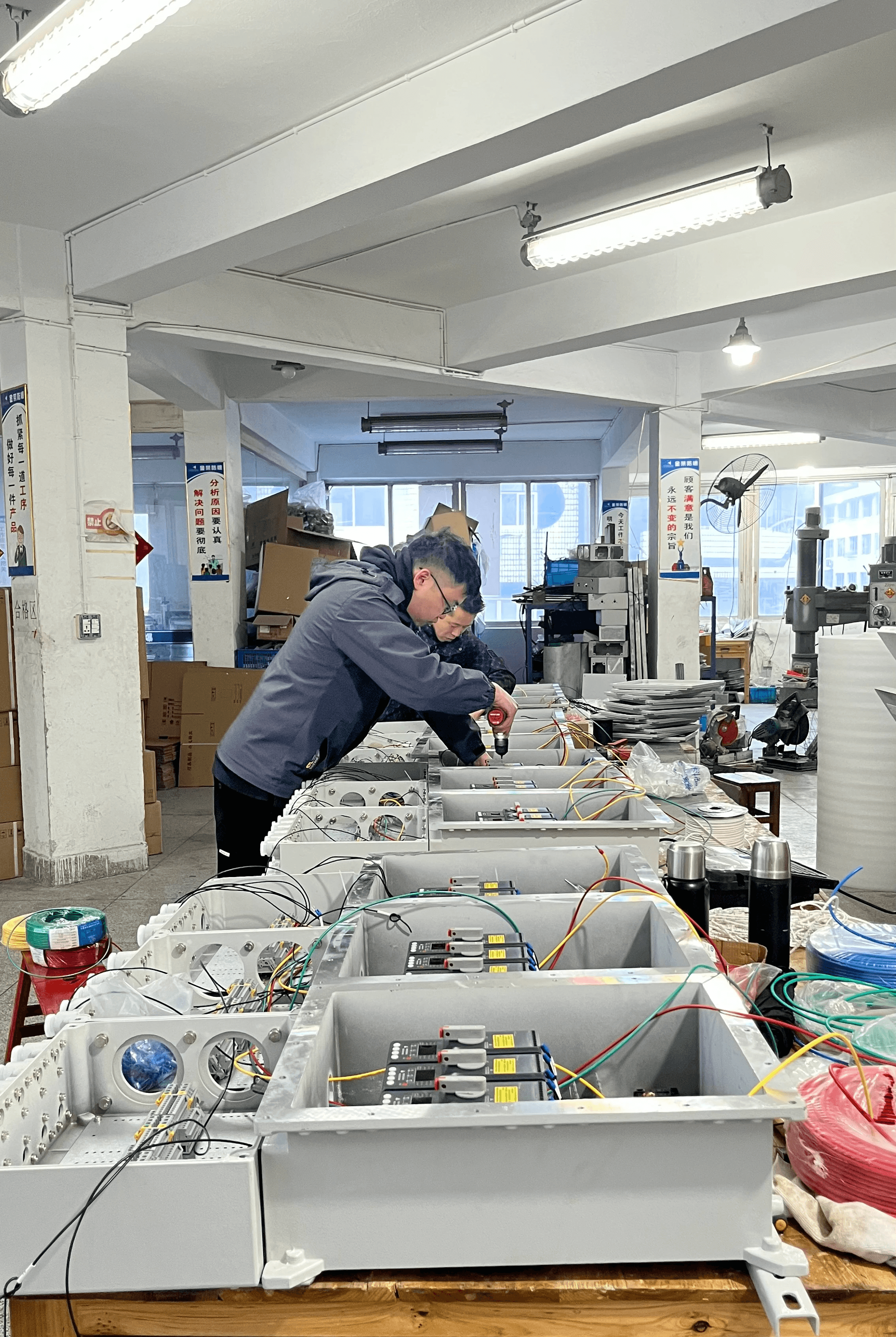

Jinrong's expertise in the field of NEMA enclosure ratings is unparalleled. The company specializes in creating robust solutions tailored for various applications, particularly those requiring a NEMA 4X rating. With a dedicated team of engineers and technicians, they are adept at addressing the unique challenges posed by different industries, ensuring their products exceed customer expectations.

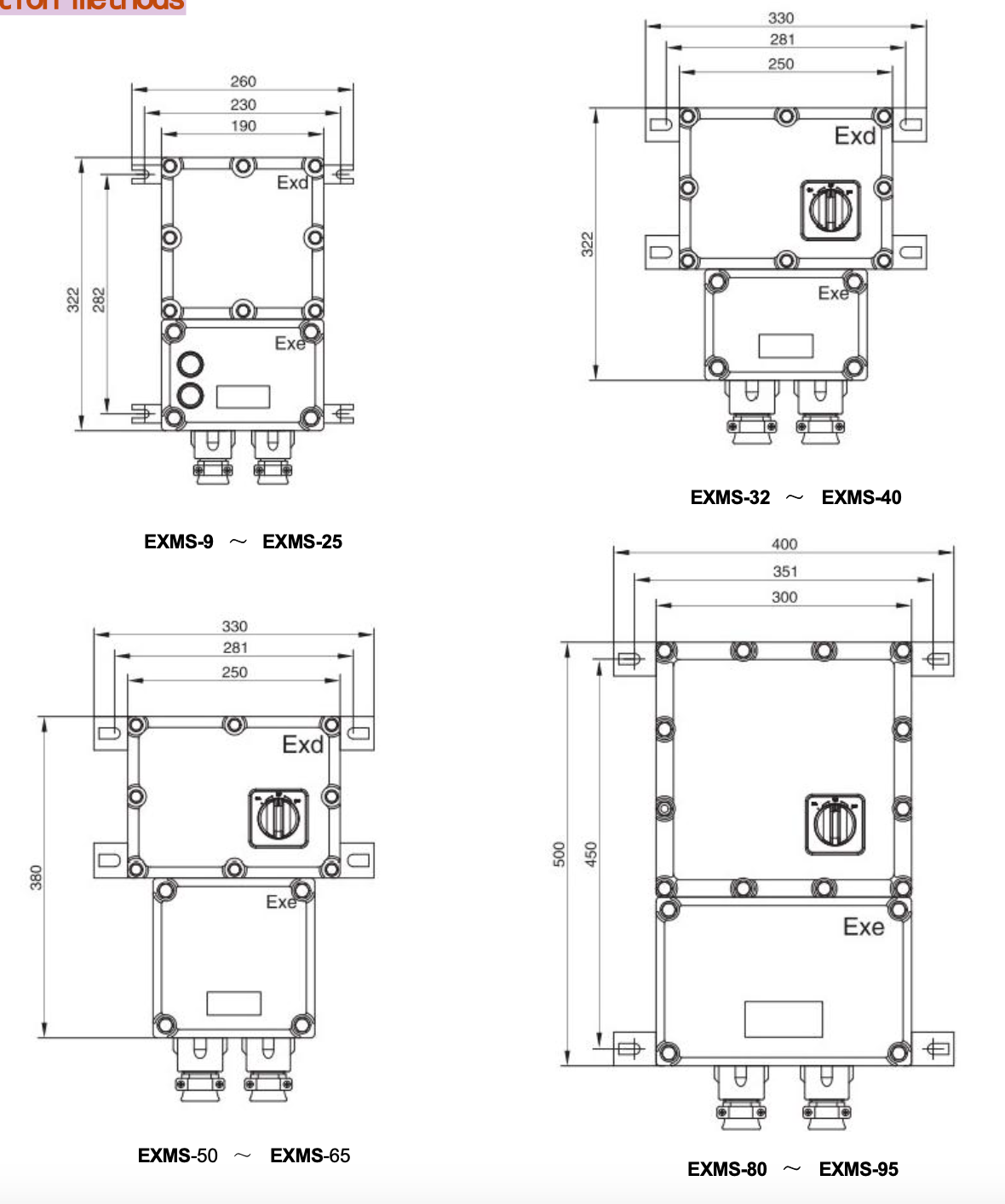

Product Range for NEMA 4X Applications

Jinrong offers an extensive product range specifically designed for applications requiring a NEMA 4X rating. This includes various sizes and configurations of NEMA 4X enclosures suitable for electrical components exposed to moisture and corrosive elements. From wall-mounted units to larger freestanding enclosures, Jinrong ensures that each product meets rigorous quality standards while providing flexibility for diverse operational needs.

Commitment to Quality and Innovation

At Jinrong, quality and innovation go hand-in-hand when it comes to manufacturing NEMA 4X enclosures. The company employs cutting-edge technology and materials that enhance durability against harsh environmental factors while maintaining compliance with all necessary regulations regarding NEMA ratings. Their relentless pursuit of improvement means customers can rely on Jinrong not only for current needs but also for future advancements in enclosure design.

Conclusion

In summary, understanding the NEMA 4X rating is essential for selecting the right enclosure for various applications. This rating not only signifies protection against water and dust but also against corrosive environments, making it a preferred choice in many industries. As technology advances and environmental conditions become more challenging, the importance of NEMA ratings—including the NEMA 4X—will continue to grow.

Key Takeaways on NEMA 4X Rating

The NEMA 4X rating stands out due to its robust features designed to withstand harsh conditions, including moisture and corrosion. It is crucial for industries that require reliable protection for electrical components, ensuring safety and longevity. Remember, while the NEMA 4 rating offers some level of protection, the additional features of a NEMA 4X enclosure make it a superior choice for demanding environments.

Selecting the Right NEMA Enclosure

Choosing the right enclosure involves considering several factors such as environmental conditions, application requirements, and specific industry standards. The versatility of a NEMA 4X electrical enclosure makes it suitable for various applications—from food processing plants to chemical manufacturing facilities. It's vital to assess your unique needs before settling on an enclosure; opting for a high-quality NEMA-rated product can save time and resources in the long run.

Future Trends in NEMA Ratings

As industries continue to evolve with new technologies and materials, we can expect future trends in NEMA ratings to reflect these changes. Innovations may lead to enhanced materials that provide even greater resistance against environmental factors while maintaining cost-effectiveness. Additionally, as sustainability becomes more critical across sectors, future developments may focus on eco-friendly enclosures that still meet stringent NEMA ratings like the robust NEMA 4X.